Superior Quality Tablet Press (Pill Press/Tablet Machine), Roll Compactor and Pharmaceutical Machines Since 1983

Fluidpack is a leading Tableting Machines, Roll Compactors, Allied and Ancillary equipments, Punches & Dyes manufacturer & supplier with objective to cater quality pill press machines since 1983 under brand name “ACCURA”. Being consistent in offering customised, quality and varied range of hi-tech Table Press Machines, we have served more than 2250 esteem clients. We provide all types (Manual, Semi-Automatic and Fully Automatic) Pill Machines. The tablet press is a mechanical device, which by use of compression, converts powder into tablets of uniform size and weight. Pill press is used to manufacture tablet of a wide variety of materials which is being used in various different industries such as pharmaceuticals, nutraceuticals, cleaning products, cosmetics, etc. In a Pill Press, the granulated material must be forced through the cavity which is formed by the punches and die. These punches then mix the material together when pressed with great force. The pill press machines are very handy machines in today’s world as quite a number of drugs are consumed in the form of a pill.

We have core expertise in manufacturing world class Pharmaceutical Machineries (cGMP Models) for domestic market as well exporting worldwide. With years of experience and constant R&D, we have developed fast paced and advance technology machines as below-

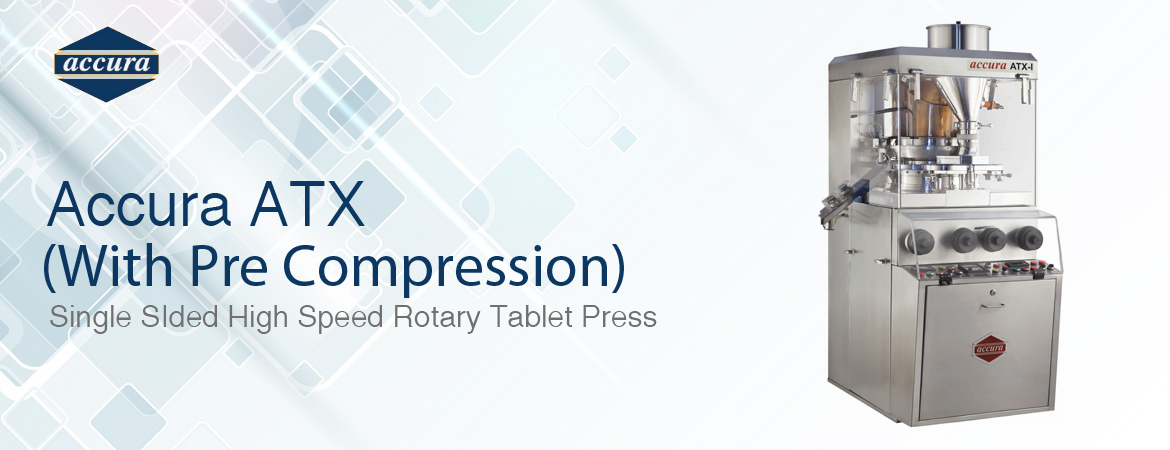

- High Speed Single sided/Double Rotary Tablet Press Machine

- High Speed Pill Press II & IV

- B4-Double Sided/D4-Single sided Rotary Tablet Press

- Single sided Tablet Slugging (Bolus) Machine

- Single & Double Layer Mini Tablet Press

- Plain & Water Jacketted Roll Compactors cGMP, R&D Roller Compactor

- Tablet De-Burring & De-Dusting Machine & Dust Extractor

- Communiting Mill, Multi Mill, Vibro Sifter, Colloid Mill, Oscillating Granulator

- Tablet Coating Machine

- Punches & Dies And more.

We are one of the leading Tablet Compression Machines manufacturers & exporters, yet to keep on boosting our quality aspects, we have made significant and required investments and up-gradation for maintaining together with building up an excellent and advanced in-house infrastructure facility.

While choosing a tableting machine a few parameters must be taken into consideration. The tablet compression machine offers some features like Main and pre-pressure values, access graphic interface, weight adjustment punch penetration, etc. If one looks at the overall hygiene part, robust, compact, and modular designs must be so formulated that there is minimum contact with the product. If there is a contact, the part should be of a good material that is stainless steel preferably. The tablet compression machine manufacturer focuses on the safety, optimizing operation, and quality of the machine. In short, the selection of a tablet compression machine should include the consideration of structural design, turret, die & punch type, automation technology, safety, and machine configuration or model.

With the leading name in technology, FLUIDPACK offers a variety of machinery in an automatic tablet compression machine that suits the cGMP standards and is most suitable for Research and development, mass production, and clinic trials. The pill press machines are used for producing tablets and pills of uniform size and shape and weights. A tableting machine manufacturer determines the overall production cost, tooling strength, premature tooling failures. The product range is ideally suited for small and medium to large batches. The users get a reliable solution with tablet presses produced at FLUIDPACK as they feature exclusive novel technologies.

This is how we have our global reach to 55 countries like U.S.A, Canada, Germany, Italy, Jordan, Syria, Turkey, Kuwait, Iran, Algeria, Argentina, Bangladesh, Bangkok, Indonesia, Malaysia, Vietnam, Nigeria, Ghana, Malawi, Egypt, Ukraine, and more with our main objective of “Better Tableting Solutions”