A tablet press is a device that compresses powder form into tablets of uniform size and weight and is extensively used in pharmaceutical industries. The force of compression is downloaded by high-pressure compression rolls which convert the granulated material and holding them together into a hard tablet. After compression is done, the lower punch is lifted to eject the tablet out.

Reasons for the Rapid Development of Tablet Press Machine

- Innovations in new technology in tablet production like the direct compression technology.

- High and stringent standards of adherence to cleanliness rolled out by the Current Good Manufacturing Process(CGMP). Cleanliness and Uniformity are well maintained by the use of these devices.

- The exponential increase in population leading to an increase in lifestyle diseases and increased demand for tablets leading to increased production.

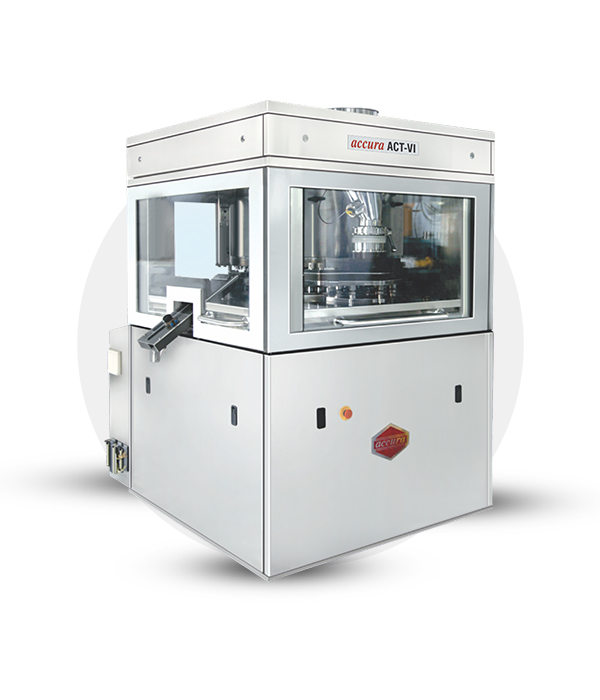

Classification of Tablet Press - Different manufacturers introduce new models of presses differing in range, speed and capacity.

Single Punch or the Single Station/Eccentric Presses - This machine uses a single tooling station with a die and pair of upper and lower punches.

Multi-Station/Rotary Presses - This has a die table and turrets that hold the punches. The upper and lower punches cater to each of the dies. The lower punch in this remains stationary while the upper punch exerts the force.

A wide range of tablet press machine and their support accessories include punch dies, tablet coating machine, sifter machines, Mills, dust extractor machines, deburring and dedusting equipment, mini press machine which all help in the functioning of tablet press machine, and all leading manufacturers of pharmaceutical product all these components.

The key features of a Tablet Press:

- They can have interchangeable turrets that help them produce annular, irregular, or engraved tablets.

- They usually have a stable and strong body which reduces any kind of noise during its working and avoids any dust settling.

- It is a safe and easy-to-use operation that can produce volumes depending on the machine used.

- Process of tableting done by the tablet press machine.

This is a two-step process in which the first step lowers the bottom punch on the die to create a gap for the granulated powder. How much the punch has to be lowered gets controlled by the machine according to the settings. Any filling that is done in excess is removed from the top by the upper punch when it comes in contact with the powder. The high compression rolls come into the play which helps in fusing the granulated material to form a hard tablet. The lower punch then ejects the tablet by raising it again.

Applications of a Tablet Press Machine-

- It is easy to use this tablet press machine and it operates at a high utilization ratio.

- It is ideal for the development of tablet and small and large batch productions.

- The multi-station ones are having high productivity with a minimal amount of labour.

- The use of these machines decreases any wastage.

- Less Maintenance cost and more affordable in price.

- Can handle a wide range of ingredients and a high volume.

- Flexibility in terms of the tools used in the machine which are re-adjustable.

These machines are very useful in the making of chewable tablets and in the making of effervescent tablets that contain tartaric acid, citric acid as well as sodium bicarbonate. The machines of the modern-day are so well designed to meet the required engineered standards as well as to deliver efficiency and productivity as per the business requirement and increasing demand.