accura

B4 - Double Sided Rotary Tablet Press Machine

Double Sided Rotary Tablet Press with 27 Stn. "D'', 27 Stn. "B", 35 Stn. "B" & 45 Stn. "BB"

- Complies with cGMP standards with a square design and all contact parts made of SS 316L material.

- Operates at speeds up to 40 RPM with 360° operational access.

- Features a 3-step gearbox for higher torque and a double hopper with a 14-liter capacity.

- Equipped with a gravity feeding system and upper punch penetration up to 8mm.

- Includes an AC variable frequency drive for RPM control with an electromagnetic clutch.

- Main turret drive motor with a capacity of 7.5 HP for D tooling and 5 HP for B tooling.

- Maximum Output: 2,16,000 Tablets per Hour

Salient Features of Double Sided Rotary Tablet Press

Machine Design

-

Double rotary tablet press

Double rotary tablet press -

Square design with comply cGMP standards

Square design with comply cGMP standards -

All contact parts made of SS 316L material

All contact parts made of SS 316L material -

Speed up to 40 RPM

Speed up to 40 RPM -

360® operational access

360® operational access -

All tablet parameters control from outside of tableting zone

All tablet parameters control from outside of tableting zone -

Plug & play design

Plug & play design -

Bi-layer operation

Bi-layer operation

Compression Zone

-

Double sided main compression roller – 100kN capacity

Double sided main compression roller – 100kN capacity -

3 steps Gearbox for higher torque

3 steps Gearbox for higher torque -

Double hopper having - 14 Liters capacity

Double hopper having - 14 Liters capacity -

Gravity Feeding system

Gravity Feeding system -

Upper punch penetration up to 8mm

Upper punch penetration up to 8mm -

AC variable Frequency drive for RPM control with Electromagnetic clutch

AC variable Frequency drive for RPM control with Electromagnetic clutch -

Turret of special grade SGI cast iron with electro less nickel plating

Turret of special grade SGI cast iron with electro less nickel plating -

Lubrication port available for upper punch head, Bar rel & Gearbox

Lubrication port available for upper punch head, Bar rel & Gearbox -

Electromagnetic clutch system for smooth start of turret & improve life of motor and gearbox

Electromagnetic clutch system for smooth start of turret & improve life of motor and gearbox -

Four side Upper Guard with safety interlock

Four side Upper Guard with safety interlock

Lower Base Cabinet

-

Main tur ret drive motor capacity of 7.5 HP in D tooling - 5 HP in B tooling

Main tur ret drive motor capacity of 7.5 HP in D tooling - 5 HP in B tooling -

Tablet Parameters control systems (Fill depth, Tablet Thickness & Compaction pressure)

Tablet Parameters control systems (Fill depth, Tablet Thickness & Compaction pressure) -

Lower pressure roller

Lower pressure roller -

Manual Lubrication system

Manual Lubrication system -

Lower guard made of SS304 Material

Lower guard made of SS304 Material

Electric Instrument & Operating

-

Electric Panel Front side at lower cabinet

Electric Panel Front side at lower cabinet -

Front side easy operating system

Front side easy operating system -

Tablet counter

Tablet counter -

Ampere counter

Ampere counter -

Indication Lamps acknowledge Alarms and status

Indication Lamps acknowledge Alarms and status

Optional Accessories

-

High speed data transfer PLC for smooth operation / 7” touch screen HMI for ease of operation

High speed data transfer PLC for smooth operation / 7” touch screen HMI for ease of operation -

Force Feeding System

Force Feeding System -

Bi-Layer Attachment

Bi-Layer Attachment -

Auto Lubrication System

Auto Lubrication System

Technical Specifications of Rotary Tablet Press Machine

| TYPE | B4-27-D | B4-27-B | B4-35-B | B4-45-BB | |

| Number of Station | 27 | 27 | 35 | 45 | |

| Type of Tooling (As per EU1) | D | B | B | BB | |

| Output-Tablets/Hour (Min / Max.)(Single Layer) | 55,080 / 1,29,600 | 55,080 / 1,29,600 | 71,400 / 1,68,000 | 91,800 / 2,16,000 | |

| Output-Tablets/Hour (Min / Max.) (Bi-Layer) | 16,200 / 40,500 | 16,200 / 40,500 | 21,000 / 52,500 | 27,000 / 67,500 | |

| Turret RPM (Min./Max.)(Single Layer) | 17 / 40 | ||||

| Turret RPM (Min./Max.)(Bi-Layer) | 10 / 25 | ||||

| Max. Operating Pressure-Main (kN) | 100 | 65 | |||

| Max. Tablet Diameter (mm) | 25 | 16 | 11 | ||

| Max. Tablet Thickness (mm) | 8.5 | ||||

| Max. Depth of Fill (mm) | 20mm | 17.5mm | |||

| Pressure Roll Diameter | 8-1/2" (215.9mm) | 8" (203mm) | |||

| Upper Punch Entry Main | 1.5 to 8mm | ||||

| Main Electric Motor (kW/hp) | 5.5 Kw / 7.5 Hp x 1440 RPM | 3.72 Kw / 5 Hp x 1440 RPM | |||

| Hopper Capacity | 15 Litres | ||||

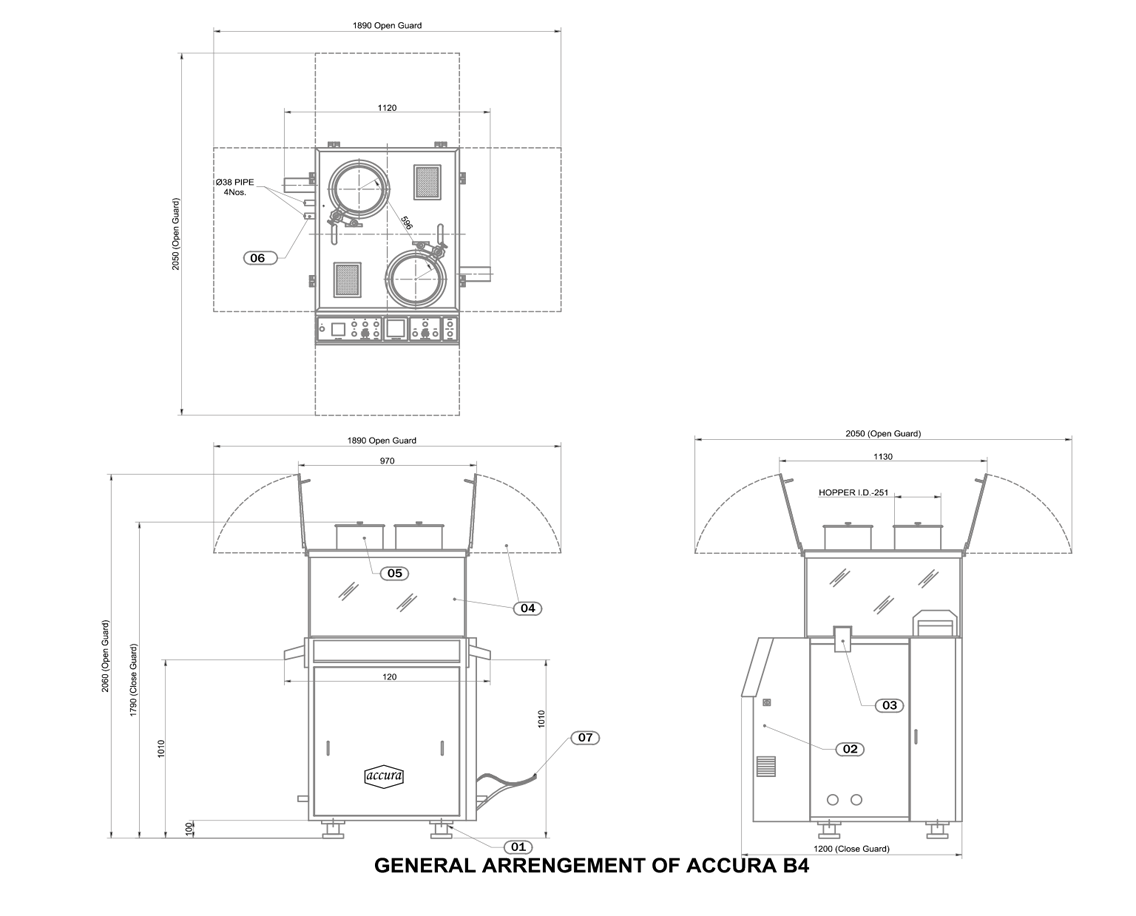

| Overall Dimensions Close Guard(cm) | 112 W x 120 L x 179 H | ||||

| Overall Dimension Open Guard(cm) | 189 W x 205 L x 206 H | ||||

| Case Dimensions(cm) | 132 W x 153 L x 210 H | ||||

| Net Weight (kg) | 1400 Kg. | ||||

| Gross Weight(kg) | 1800 Kg | ||||

| Utilities: | 1) Suction Air: | 150 CFM (Qty. - 01 for Single Layer) 150 CFM (Qty.- 02 for Bi Layer) |

|||

| 2) Power Supply: | (a) 415 V, 3 Phase, 50 Hz (b) 480 V, 3 Phase, 60 Hz (c) 220 V, 3 Phase, 60 Hz |

||||

| 3) Power-Total (kw/hp): | 8.63 kW / 11.50 hp | ||||

* Depending upon material characteristics & available room atmosphere only.

NOTE: DUE TO CONTINUOUS IMPROVEMENTS IN THE MACHINERY, THE SPECIFICATION OF THE MACHINERY IS SUBJECT TO CHANGE WITHOUT ANY PRIOR NOTICE.

Pre-pressure and Main pressure could be changed depending on the size of the compress and filling depth, powder or granulation. It depends on the physical specification of the used material for the compress.

The above specification is subject to change without prior notice for the technical development.

It is recommended not to use a large depth of fill, minimum tablet thickness, and maximum compression pressure consistently for maximum performance.

Technical rights to change catalogs, specifications, and features are reserved with the manufacturer. Actual output may vary against indicated output on the product under compression and RPM on the lower side.

Rotary Tablet Press Drawing

FAQs - Double Sided Rotary Tablet Press Machine

Double Sided Rotary Tablet Press Machine is a high-speed mechanical device used in the pharmaceutical and related industries to compress powder into tablets. It utilizes both sides of the machine for compression, allowing for higher production rates.

This machine works by compressing granulated material into tablets using a combination of punches and dies. The process involves powder filling, compression, and tablet discharge, resulting in efficient and high-volume tablet production.

These machines are primarily used in the pharmaceutical industry but are also applicable in nutraceuticals, cosmetics, and cleaning products industries for tablet manufacturing.

Advantages include:

- High production capacity, capable of producing up to 216,000 tablets per hour.

- Enhanced efficiency and speed due to the double-sided compression mechanism.

- Consistent and precise tablet size and shape.

- Compliance with cGMP standards, ensuring high quality and safety.

Yes, it can handle a variety of tablet sizes and shapes by changing the punches and dies. Different models offer varying maximum tablet diameters to accommodate different production needs.

Consider factors such as:

- Production capacity requirements.

- Type of tooling needed (B, D, BB).

- Specific features like electronic controls, safety guards, dust extraction systems, and lubrication systems.

- Compliance with industry standards such as cGMP.

Yes, these machines can be fully or partially automated, allowing for precise control over tablet weight, hardness, and overall production process, enhancing efficiency and reducing manual intervention.

Regular maintenance includes:

- Cleaning and lubrication of moving parts.

- Inspection and replacement of worn-out punches and dies.

- Checking and adjusting machine settings to ensure consistent production quality.

- Ensuring the dust extraction system and safety features are functioning correctly.

Optional features may include:

- AC variable drive and electromagnetic clutch.

- Force feeding with AC drive attachments.

- Two-layer tablet attachment.

- PLC with MMI and color touch screen.

- Enhanced turret options with electroless nickel plating and stainless steel die plates.

The dust extraction system helps maintain a clean manufacturing environment by effectively removing dust generated during the tablet compression process, which is crucial for ensuring product quality and complying with hygiene standards.

Want to know more

about the B4 - Double Sided Rotary Tablet Press Machine?

Send us a message

All fields marked (*) are mandatory.

Please do not hesitate to contact us if you require more information and detailed advice. We look forward to receiving your phone call or email.