Salient Features

-

It is a high speed double rotary tablet press for higher tablet output.

It is a high speed double rotary tablet press for higher tablet output. -

Machine is having a square design with full consideration of cGMP standards.

Machine is having a square design with full consideration of cGMP standards. -

The machine is having PRE-COMPRESSION facility.

The machine is having PRE-COMPRESSION facility. -

The machine is having A.C. variable frequency drive for the main motor.

The machine is having A.C. variable frequency drive for the main motor. -

The machine is having Electromagnetic clutch arrangements.

The machine is having Electromagnetic clutch arrangements. -

The machine having Motorized Hydraulic Power pack for pressure loading and overload release.

The machine having Motorized Hydraulic Power pack for pressure loading and overload release. -

The machine is having Helical gear ring & pinion gear, to drive the turret.

The machine is having Helical gear ring & pinion gear, to drive the turret. -

All upper Guards of transparent acrylic material with interlock switches for safety.

All upper Guards of transparent acrylic material with interlock switches for safety. -

Lower Guards of polished Stainless Steel SS 304.

Lower Guards of polished Stainless Steel SS 304. -

The machine is having excellent bottom driven force feeding system for material feeding.

The machine is having excellent bottom driven force feeding system for material feeding. -

The machine is having one piece turret of special grade casting. However, three piece turret

The machine is having one piece turret of special grade casting. However, three piece turret -

Two layer attachments can also be provided (Optionally).

Two layer attachments can also be provided (Optionally). -

PLC with colour HMI touch screen (Optionally).

PLC with colour HMI touch screen (Optionally). -

All the tablet parameters can be fine tuned during the operation of the machine from outside the Tabulating zone, with front controls at outside of the machine, having SEIKO type dials.

All the tablet parameters can be fine tuned during the operation of the machine from outside the Tabulating zone, with front controls at outside of the machine, having SEIKO type dials. -

The machine is having A.C. variable frequency drive for force feeding motors, Which enables operators to synchronize machine's speed & feed both.

The machine is having A.C. variable frequency drive for force feeding motors, Which enables operators to synchronize machine's speed & feed both.

With Auto Force Rejection Through Compaction Force

-

With load cell at Main Compression for Pressure measurement.

With load cell at Main Compression for Pressure measurement. -

With auto sampling based on, either time or revolution of punch no.

With auto sampling based on, either time or revolution of punch no. -

With auto rejection of any single tablet out of prescribed compaction force limit.

With auto rejection of any single tablet out of prescribed compaction force limit. -

SCADA with industrial PC. having 15” colour touch screen (21 CFR part 11 compliance)

SCADA with industrial PC. having 15” colour touch screen (21 CFR part 11 compliance) -

With graphical as well as numeric representation of each individual punch force.

With graphical as well as numeric representation of each individual punch force.

Technical Specifications

| TYPE | PRESS V-51 | PRESS V-65 | PRESS V-81 |

| Number of Station | 51 | 65 | 81 |

| Type of Tooling (As per EU1) | D | B | BB |

| Output-Tablets/Hour (Min./Max.)(Single Layer) | 73,440 / 4,28,400 | 93,600 / 5,46,000 | 1,16,640 / 6,80,400 |

| Output-Tablets/Hour (Min/Max.) (Bi-Layer) | 36,720 / 1,07,100 | 46,800 / 1,36,500 | 58,320 / 1,70,100 |

| Turret Speed (RPM) (Min./Max.) (Single Layer) | 12 / 70 | ||

| Turret Speed RPM (Min./Max.) (Bi-Layer) | 12 / 35 | ||

| Max. Operating Pressure-Main (kN) | 100 | 65 | |

| Max. Operating Pre. Pressure-Tamp.(kN) | 20 | ||

| Max. Tablet Diameter (mm) | 25 | 16 | 11 |

| Max. Tablet Thickness (mm) | 8.5 | ||

| Depth Of Fill(With Three Different Lower Track) | 13/16", 9/16", 5/16" | 11/16", 1/2", 5/16" | 11/16", 1/2", 5/16" |

| Upper Punch Entry Main (mm) | 1.5 To 8 mm | ||

| Upper Punch Entry Pre-Comp. (mm) | 1.5 To 8 mm | ||

| Main Ele. Motor (kw/hp) | 11 kW / 15 hp x 1440 RPM | ||

| Feeder Ele. Motor (kw/hp) | 0.1875 kW / 0.25 hp, x 1440 RPMx2 Nos.=0.375 kW / 0.50 hp | ||

| Power Pack Motor | 0.75 kW / 1 hp | ||

| Continuous Lubrication Pump | 0.0375 kW / 0.05hp | ||

| Pinion With Helical Ring(Dropco Pump) | |||

| Hopper Capacity | 20 Litres | ||

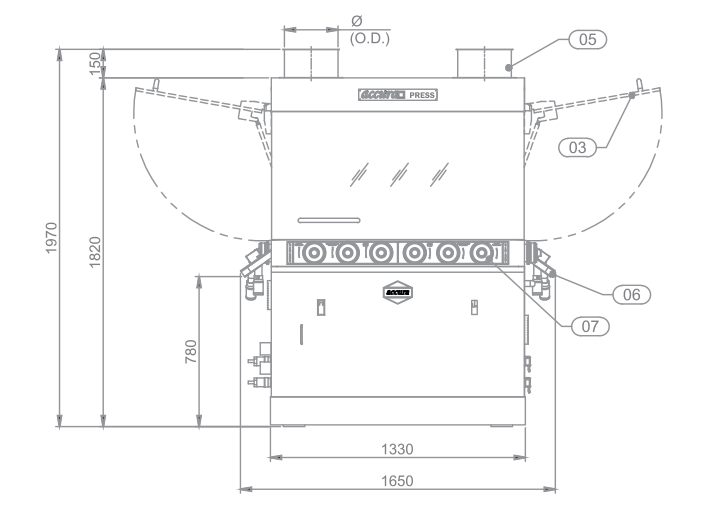

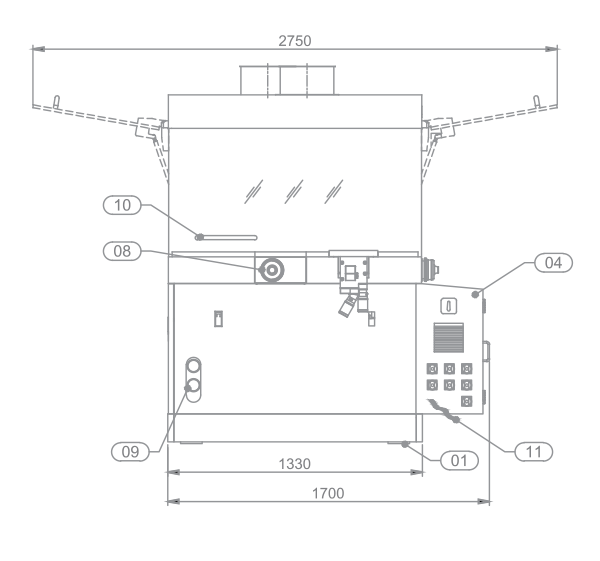

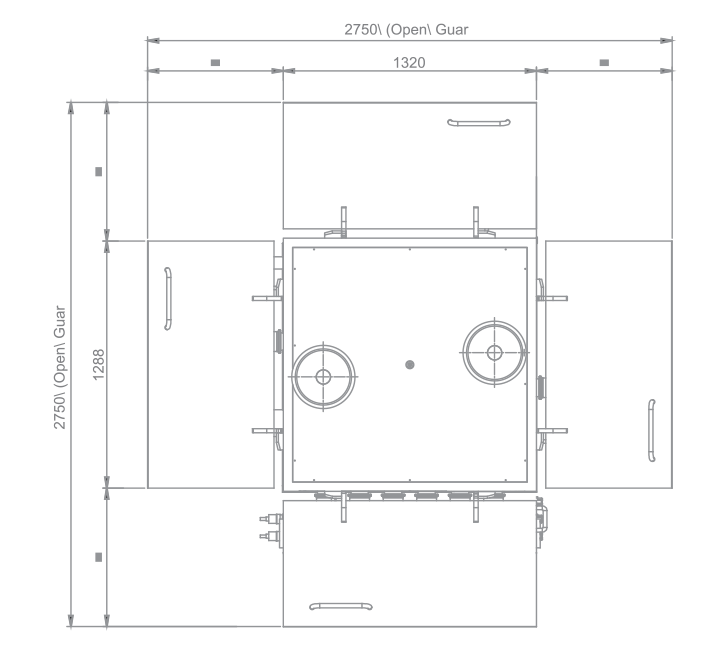

| Overall Dimensions Close Guard-cm | 170 L x 165 W x 197 H | ||

| Overall Dimension Open Guard -cm | 275 L x 275 W x 197 H | ||

| Net Weight (kg) | 4100 Kg. (Approx.) | ||

| Utilities : | 1) Suction Air : | 300 CFM (Qty. - 01 for Single Layer) 300 CFM (Qty.- 02 for Bi-Layer) |

|

| 2) Compressed Air : | 7Kg/Sq.cm (7 Bar) | ||

| 3) Power Supply : | (a) 415 V, 3 Phase, 50 Hz (b) 480 V, 3 Phase, 60 Hz (c) 220 V, 3 Phase, 60 Hz |

||

| Power-Total (kw/hp) : | 12.16 kW / 16.22 hp | ||

* Depending upon material characteristic & available room atmosphere only.

NOTE : DUE TO CONTINUOUS IMPROVEMENTS IN THE MACHINERIES, SPECIFICATION OF THE MACHINERIES IS SUBJECT TO CHANGE WITHOUT ANY PRIOR NOTICE.

Pre-pressure and Main pressure could be changed depending on the size of the compress and filling depth, powder or granulation. It is dependent on the physical specification of the used material for the compress.

The above specification is the subject to change without prior notice for the technical development.

It is Recomended not to use large depth of fill, minimum tablet thickness and maximum compression pressure for maximum performance consistently.

Technical rights to change catalogues, specifications and features are reserved with the manufacturer. Actual output may vary against indicated output on the product under compression and RPM on lower side.

Drawing

Want to know more

about the Double Rotary High Speed Tablet Press V?

Send us a message

All fields marked (*) are mandatory.

Please do not hesitate to contact us if you require more information and detailed advice. We look forward to receiving your phone call or email.