accura

F7200 High Speed Double Rotary Tablet Compression Machine

F 7200

High Speed Double Rotary Tablet Press

- With Pre-compression 10 Tons & Main Compression 10 Tons

- Maximum Output - 7,77,600 Tablets / Hour.

- With Interchangeable Turret.

- Auto Weight Through Compaction Force Control.

- Auto Tablet Rejection Through Compaction Force Control.

- 51 Stn "D" Tooling / 65 Stn "B" Tooling / 77 Stn "Bb" Tooling / 81 Stn "Bbs" Tooling

Salient Features

-

Double Rotary Tablet Press With Interchangeable Turret. (In Compliance with cGMP.)

Double Rotary Tablet Press With Interchangeable Turret. (In Compliance with cGMP.) -

Motorized Lower Pre- Compression of 10 TONS. (100 KN)

Motorized Lower Pre- Compression of 10 TONS. (100 KN) -

Manual Upper Pre & Main Punch Penetration system (2mm - 8 mm).

Manual Upper Pre & Main Punch Penetration system (2mm - 8 mm). -

Motorized force feeder with AC VFD & with Zero Clearance, Three Paddles Force Feeding System.

Motorized force feeder with AC VFD & with Zero Clearance, Three Paddles Force Feeding System. -

Fully Computerized PLC Based Industrial PC, having 19” Colour Touch Screen Control.

Fully Computerized PLC Based Industrial PC, having 19” Colour Touch Screen Control. -

Machine is Four Side open with interlock switches to all acrylic upper guards & SS-304 Lower guards.

Machine is Four Side open with interlock switches to all acrylic upper guards & SS-304 Lower guards. -

With Easy Turret Exchangeable Turret Facility.

With Easy Turret Exchangeable Turret Facility. -

Any Turret of D-B-BB-BBS Tooling which is a part of this F-7200 model can be fitted.

Any Turret of D-B-BB-BBS Tooling which is a part of this F-7200 model can be fitted. -

Encoder System for Better Accuracy.

Encoder System for Better Accuracy. -

Graphical appearance of the value of pressure on individual punch at pre and main pressure.

Graphical appearance of the value of pressure on individual punch at pre and main pressure. -

The after sales, PLC Complaints can be carried out by internet Thru Team Viewer.

The after sales, PLC Complaints can be carried out by internet Thru Team Viewer. -

Turret Lifting by External Hydraulic Jack Trolley. (Optional)

Turret Lifting by External Hydraulic Jack Trolley. (Optional)

-

3 Piece Turret With Die - Table SS-316 & Upper & lower Piece Electro-Les Nickel Plated.

3 Piece Turret With Die - Table SS-316 & Upper & lower Piece Electro-Les Nickel Plated. -

Motorized Lower Main Compression of 10 TONS. (100 KN)

Motorized Lower Main Compression of 10 TONS. (100 KN) -

Motorized Dozzer, for precise Depth of Fill adjustment.

Motorized Dozzer, for precise Depth of Fill adjustment. -

Load cell at Pre- Pre-Compression & Main Compression.

Load cell at Pre- Pre-Compression & Main Compression. -

Vibration-free and easy to operate at 80 RPM.

Vibration-free and easy to operate at 80 RPM. -

Sliding Type Per & Main Upper Pressure Roll Assembly.

Sliding Type Per & Main Upper Pressure Roll Assembly. -

Initial Start up & Stop Rejection. & Auto Sampling based on, either time or revolution or punch nos.

Initial Start up & Stop Rejection. & Auto Sampling based on, either time or revolution or punch nos. -

Auto Weight Control & Single Tablet Rejection Through Compaction Force Control - CFC. (AWC & AFR).

Auto Weight Control & Single Tablet Rejection Through Compaction Force Control - CFC. (AWC & AFR). -

Powder Level Sensor @ Hopper and Force feeder (Low-level sensor). Auto Lubrication.

Powder Level Sensor @ Hopper and Force feeder (Low-level sensor). Auto Lubrication. -

Recipe management & 'n' No. of recipe storage.

Recipe management & 'n' No. of recipe storage. -

Audit trail reports, and pen drive connectivity with printing facility.

Audit trail reports, and pen drive connectivity with printing facility. -

Bi-Layer System. (Optional)

Bi-Layer System. (Optional) -

Turret Resting Trolley. (Optional)

Turret Resting Trolley. (Optional) -

Ejection Force Monitoring Available with CFC System. (Optional)

Ejection Force Monitoring Available with CFC System. (Optional)

The software part of F 7200

-

Auto weight control is available through Compaction force.

Auto weight control is available through Compaction force. -

System is 21 CFR part 11 Compliance.

System is 21 CFR part 11 Compliance. -

Multi users password and user authorization.

Multi users password and user authorization. -

Individual users access rights.

Individual users access rights. -

Encoders for counting all the parameters.

Encoders for counting all the parameters. -

Individual tablet rejection(beyond weight) through compaction force.

Individual tablet rejection(beyond weight) through compaction force. -

“Accura mode” for eliminating weight variation at higher speed.

“Accura mode” for eliminating weight variation at higher speed. -

19” touch screen IPC for the operating system.

19” touch screen IPC for the operating system. -

Feeder synchronization.

Feeder synchronization. -

Initial tablet rejection during start/stops.

Initial tablet rejection during start/stops. -

Production Mode / Set up mode.

Production Mode / Set up mode. -

Manual Run/Jog Run / Auto Run.

Manual Run/Jog Run / Auto Run.

-

Pre-compression punch force (Individual station).

Pre-compression punch force (Individual station). -

Main Compression punch force (Individual station).

Main Compression punch force (Individual station). -

Auto Sampling Mode.

Auto Sampling Mode. -

Based on Time/Punches or No. of tablets.

Based on Time/Punches or No. of tablets. -

Auto Lubrication.

Auto Lubrication. -

Recipe creation/download/Edit option.

Recipe creation/download/Edit option. -

Various types of print reports.

Various types of print reports. -

Auditable reports and history.

Auditable reports and history. -

Individual punch force details.

Individual punch force details. -

Auto printing option.

Auto printing option. -

Operating SOP, Cleaning Procedure, Maintenance Guide, Electrical Drawing & Pneumatic Drowing Available in IPC as a PDF Form.

Operating SOP, Cleaning Procedure, Maintenance Guide, Electrical Drawing & Pneumatic Drowing Available in IPC as a PDF Form.

Technical Specifications

| TYPE | F 7200 - 51 D | F 7200 - 65 B | F 7200 - 77 BB | F 7200 - 81BBS |

| Number of Station | 51 | 65 | 77 | 81 |

| Type of Tooling (As per EU1) | D | B | BB | BBS |

| Output-Tablets/Hour (Min/Max.) (Single Layer) | 30600 /490000 | 39000 / 624000 | 46200 / 739200 | 145800 / 777600 |

| Output-Tablets/Hour (Min/Max.) (Bi-Layer) | 15300 /122400 | 19500 / 156000 | 23100 / 184800 | 24300 / 194400 |

| Turret RPM (Min./Max.) (Single Layer) | 5/80 | |||

| Turret RPM (Min./Max.) (Bi-Layer) | 5/40 | |||

| Max. Operating pressure-Main (kN) | 100 | 100 ** | ||

| Max. Operating Pre.Pressure-Tamp.(kN) | 100 | 100 ** | ||

| Max. Tablet Diameter (mm) | 25 | 16 | 13 | 11 |

| Max. Depth of Fill (mm) | 20 | 18 | 18 | 18 |

| Max. Tablet Thickness (mm) | 8.5 | |||

| Upper Punch Entry Main (mm) | 2 To 8 | |||

| Upper Punch Entry Pre-Compression (mm) | 2 To 8 | |||

| Main Torque Drive Ele. Motor (kW/hp) | 26kW/35hp x 100 RPM | |||

| Main & Pre- Press Roll Servo Motor (kW/hp) | 0.75/1.0 x 3000 RPM x 4 Nos. = 3.0 / 4.0 kW/hp | |||

| Weight Adj. Ele. Motor (kW/hp) | 0.75/1.0 x 3000 RPM x 2 Nos. = 1.50 / 2.0 kW/hp | |||

| Feeder Ele. Motor (kW/hp) | 0.37/0.50 x 1365 RPM x 2 Nos. = 0.74 / 1.0 kW/hp | |||

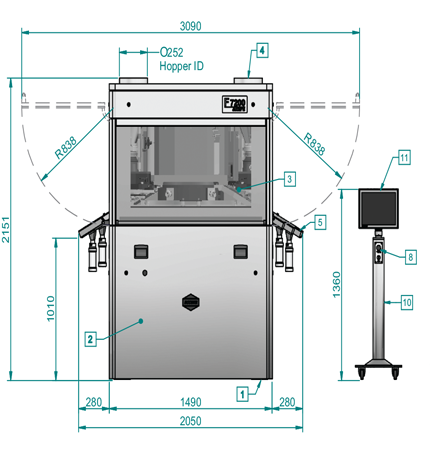

| Hopper Capacity | 19 Litres | |||

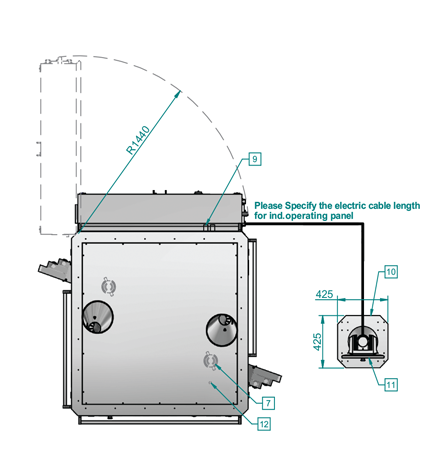

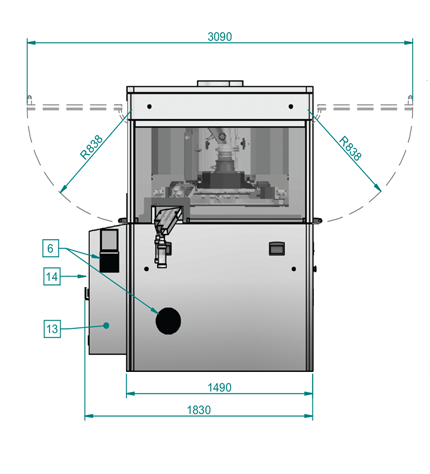

| Overall Dimensions Close Guard- cm | 149 W x 182 L x 215 H | |||

| Overall Dimension Open Guard- cm | 309 W x 309 L x 215 H | |||

| Case Dimensions (cm) | 245 W x 220 L x 225 H | |||

| Net Weight (kg) | 6400 Kg. | |||

| Gross Weight(kg) | 6800 Kg | |||

| Utilities | Suction Air: 300 CFM (Qty. - 01 for Single Layer) - 300 CFM (Qty.- 02 for Bi Layer) | |||

| Compressed Air: 7Kg/Sq.cm (7 Bar) | ||||

| Power Supply: 415V, 3 Phase, 50 Hz 480V, 3 Phase, 60 Hz 220V,3 Phase,60 Hz |

||||

| Power-Total (kw/hp): 31.24kW / 42hp | ||||

* Depending upon material characteristics & available room atmosphere only.

NOTE: DUE TO CONTINUOUS IMPROVEMENTS IN THE MACHINERY, THE SPECIFICATION OF THE MACHINERY IS SUBJECT TO CHANGE WITHOUT ANY PRIOR NOTICE.

Pre-pressure and Main pressure could be changed depending on the size of the compress and filling depth, powder or granulation. It is dependent on the physical specification of the used material for the compress.

The above specification is subject to change without prior notice for the technical development.

It is recommended not to use large depth of fill, minimum tablet thickness, and maximum compression pressure for maximum performance consistently.

Technical rights to change catalogs, specifications, and features are reserved with the manufacturer. Actual output may vary against indicated output on the product under compression and RPM on the lower side.

Safety Features of F 7200

-

Emergency Stops switches for four sides of the machine.

Emergency Stops switches for four sides of the machine. -

Motors overload precaution.

Motors overload precaution. -

AC VFD overload precaution.

AC VFD overload precaution. -

Servo motors movement notification.

Servo motors movement notification. -

Servo motors safety precaution.

Servo motors safety precaution. -

Fill cam identification.

Fill cam identification. -

Tooling safety features.

Tooling safety features. -

Tablet Rejection control alarm.

Tablet Rejection control alarm. -

Hopper powder level low/feeder powder level sensor

Hopper powder level low/feeder powder level sensor

-

High Tablet rejection notification.

High Tablet rejection notification. -

Guards interlock.

Guards interlock. -

Lubrication oil level identification.

Lubrication oil level identification. -

Low powder level.

Low powder level. -

The encoder position disturbs the alarm.

The encoder position disturbs the alarm. -

Individual compaction forces higher alarm.

Individual compaction forces higher alarm. -

Hand wheel guard notification.

Hand wheel guard notification. -

Feeder jamming sensor.

Feeder jamming sensor.

Controlling Features

-

CFC & AFR (Auto Force Rejection) Available

CFC & AFR (Auto Force Rejection) Available -

18” touchscreen IPC With 500 GB internal Memory

18” touchscreen IPC With 500 GB internal Memory -

Single Tablet Rejection Beyond Weight Limit

Single Tablet Rejection Beyond Weight Limit -

21CFR Part 11 Compliance

21CFR Part 11 Compliance -

Pre&main Compression Force Monitoring System

Pre&main Compression Force Monitoring System -

Lower Punch Tightness

Lower Punch Tightness -

Ejection Force Measuring

Ejection Force Measuring -

Upper Punch Tightness

Upper Punch Tightness -

Initial M/c Start/stop Auto Rejection

Initial M/c Start/stop Auto Rejection -

Soft Start

Soft Start

-

Recipe Reports

Recipe Reports -

Batch Reports

Batch Reports -

Audit Reports

Audit Reports -

Alarm Reports

Alarm Reports -

“accura” Awc Mode

“accura” Awc Mode -

Printing Facility All Reports

Printing Facility All Reports -

Automatic Encoder Calibration

Automatic Encoder Calibration -

Graphically Bar Graph & Punch Force Screen available With Print Option

Graphically Bar Graph & Punch Force Screen available With Print Option -

Minimum Time To Set New Product

Minimum Time To Set New Product -

Sampling-Based On Punch No/ No Of Tablet / Time Interval

Sampling-Based On Punch No/ No Of Tablet / Time Interval

Drawing

Want to know more

about the F7200 High Speed Double Rotary Tablet Compression Machine?

Send us a message

All fields marked (*) are mandatory.

Please do not hesitate to contact us if you require more information and detailed advice. We look forward to receiving your phone call or email.