accura

Roll Compactor cGMP

- 200 X 150 (W) & 200 (W) Plain & Water Jacketed cGMP

- Useful for Formulation as well as API Units.

- Safety slipping clutch between gearbox and feed screw.

- Available with Corrugated, Knurling & Briquetted Rollers.

- Available with the arrangement of Online Roll Compactor Machine Screw is driven through A.C. Drive.

Salient Features of Roll Compactor

-

In Compliance with cGMP guidelines.

In Compliance with cGMP guidelines. -

Useful for Formulation as well as API Units.

Useful for Formulation as well as API Units. -

Available with Corrugated, Knurling & Briquetted Rollers.

Available with Corrugated, Knurling & Briquetted Rollers. -

Contact Parts are made of S.S. 316 except rollers.

Contact Parts are made of S.S. 316 except rollers. -

Very compact design available in Plain, Water Jacketed, or Flameproof Models.

Very compact design available in Plain, Water Jacketed, or Flameproof Models. -

Screw is driven through AC Variable Frequency Drive. Safety slipping clutch between the gearbox and feed screw.

Screw is driven through AC Variable Frequency Drive. Safety slipping clutch between the gearbox and feed screw. -

ELNP (Electroless Nickel Plating) or Hard chrome plated with mirror-finished compacting rolls made of tools steel.

ELNP (Electroless Nickel Plating) or Hard chrome plated with mirror-finished compacting rolls made of tools steel. -

Pre-Compression chamber guides the products to roll without any slippage or leakage.

Pre-Compression chamber guides the products to roll without any slippage or leakage. -

AC Variable frequency drive for Rollers. (optional)

AC Variable frequency drive for Rollers. (optional) -

Pre-densifier screw comprises of cylindrical or conical shape, which is well polished and made of AISI SS-316 quality material.

Pre-densifier screw comprises of cylindrical or conical shape, which is well polished and made of AISI SS-316 quality material. -

The feed screw assembly can be lifted by a hand-operated hydraulic pump. This facilitates ease in cleaning.

The feed screw assembly can be lifted by a hand-operated hydraulic pump. This facilitates ease in cleaning. -

Scrapper assembly is also designed to be dismantled for ease of cleaning.

Scrapper assembly is also designed to be dismantled for ease of cleaning. -

Electrical interlocking between main roll drive and fixed screw drive.

Electrical interlocking between main roll drive and fixed screw drive. -

Water jacketing arrangement. (optional)

Water jacketing arrangement. (optional) -

Hydraulic power pack system for Rear Roller. (optional)

Hydraulic power pack system for Rear Roller. (optional) -

Rolls drive through a twin shaft gearbox with a drive unit coupled to it using a coupling, which ensures synchronization of the rolls with a steady torque loading.

Rolls drive through a twin shaft gearbox with a drive unit coupled to it using a coupling, which ensures synchronization of the rolls with a steady torque loading. -

A separate panel board which consists of all controls and indicators of the compactor is permanently built in namely, on/off rolls, on/off feed screw, main switch, forward/reverse switch, ammeters for rolls, and feed screw, and an emergency stop to avoid short circuit or fire hazard at the time of cleaning with water.

A separate panel board which consists of all controls and indicators of the compactor is permanently built in namely, on/off rolls, on/off feed screw, main switch, forward/reverse switch, ammeters for rolls, and feed screw, and an emergency stop to avoid short circuit or fire hazard at the time of cleaning with water.

Technical Specifications

| MODEL | ACRA-RC-200/150 | ACRA-R-200/200 |

| Output* | 50 to 350 Kgs / hour | 100 to 400 Kgs / hour |

| Roll Size | 200mm Dia X 150 mm (W) | 200mm Dia X 200 mm (W) |

| Roll Speed (Step Pulley drive) | 6 to 22 RPM | |

| Feed Screw Speed (Through A.C. Drive) | 5 to 60 RPM | |

| Roll Drive Motor | 10 HP, 960 RPM, 440 V, 3 Phase, 50 Hz | |

| Feed Screw Drive Motor | 5 HP, 1440 RPM, 440 V, 3 Phase, 50 Hz | |

* Depending upon material characteristic & available room atmosphere only.

Roll Compactor Machine also called as powder compactor/granulator is used for dry granulation method. It forces the fine powders between two counter rotating rollers and presses the fine powders in a solid compact or sheets, so called chips or flakes. Finally these chips or flakes are then reduced in size to the desired granules/grain size further with the help of Oscillating Granulator Machine or Multi Mill Machine or Comminuting Mill or Sizing Machine. The sieve size should be selected very carefully in order to prevent the generation of fines. The selected sieve defines the final granules/grains size. Also further to achieve excellent granules/grains can be made dust free by Screening (Sifter) Machine. The separated fines also can be Re-compacted/ Recycle with Roll Compactor Machine.

In the process of compaction, the fine powder or crystalline powder is fed to the charging hopper of the Roll Compactor. Here the vertical feed screw feeds the powder into the compacting zone of the compacting rollers through the pre-compacting chamber. The adjustable speed (through AC Variable Frequency Drive – AC VFD) of the feed screw pressures the powder to pass strictly between the compacting rollers gap and therefore strong/hard chips/flakes form from the fine or crystalline powder. After proper synchronization of Roller Speed & Feed Screw Speed with proper flakes quality, the same speed ratio can be continued to achieve more output (if the speed limit permits the machine-rated roller & feed screw speed) from the same machine model.

The Roller surface can be selected depending on the characteristics of the powder/product. If the products are well familiar with the Roll Compactor Machine, our Technical Team can suggest the perfect roller surface for the particular product based on experience & expertise it. For product development or evaluation of product or changing the concept of granulation method, or achieving the dust-free granules to get the Export quality granules, we are always happy to carry out the trails with your material in our plant.

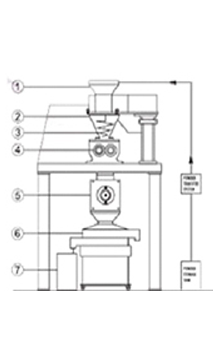

AVAILABLE ONLINE ROLL COMPACTOR

-

Powder Charging Hopper

Powder Charging Hopper -

Powder Feeding Hopper

Powder Feeding Hopper -

Powder Feed Screw

Powder Feed Screw -

Compacting Roller

Compacting Roller -

Granulator

Granulator -

Sifter

Sifter -

Storage Drum

Storage Drum

Drawing

Want to know more

about the Roll Compactor cGMP?

Send us a message

All fields marked (*) are mandatory.

Please do not hesitate to contact us if you require more information and detailed advice. We look forward to receiving your phone call or email.